Aluminum is one of the most versatile and widely used metals in the world, found in everything from kitchen utensils to aerospace components. Yet, a common question lingers in the minds of many: Does aluminum rust? This blog dives into the science behind aluminum’s behavior, its resistance to corrosion, and why it stands out among other metals. Whether you’re a manufacturer, or simply curious, understanding aluminum’s properties can help you make informed decisions about its use and maintenance.

Will Aluminum Rust?

The short answer is no—aluminum does not rust in the same way that iron-based metals do. Rust is a specific form of corrosion that occurs when iron or steel reacts with oxygen and moisture to form iron oxide, a reddish, flaky substance. Aluminum, however, is a non-ferrous metal, meaning it contains no iron and therefore cannot form rust in the traditional sense.

Instead of rusting, aluminum undergoes a different process when exposed to the elements. When aluminum comes into contact with oxygen, it naturally forms a thin, protective layer of aluminum oxide on its surface. This layer is incredibly stable and adheres tightly to the metal, acting as a barrier that prevents further degradation. Unlike rust, which continues to eat away at iron, this oxide layer helps aluminum resist further corrosion under most conditions.

Why Doesn’t Aluminum Rust?

The key to answering Why doesn’t aluminum rust? lies in its chemical properties. When aluminum comes into contact with oxygen, it forms a thin, microscopic layer of aluminum oxide on its surface. This layer is highly stable and adheres tightly to the metal, preventing further oxidation. Unlike rust, which flakes off and exposes more iron to corrosion, aluminum oxide remains intact, protecting the underlying metal.

This self-protecting mechanism is why aluminum is often used in environments prone to moisture or harsh weather. For example, aluminum components in machining processes, such as those used in CNC machining, benefit from this property, ensuring longevity and reliability. The oxide layer is also self-repairing; if scratched or damaged, it reforms quickly in the presence of oxygen, further enhancing aluminum’s durability.

However, this doesn’t mean aluminum is entirely immune to environmental damage. While it doesn’t rust, aluminum can corrode under specific circumstances, which we’ll explore further in the next section.

Does Aluminum Corrode?

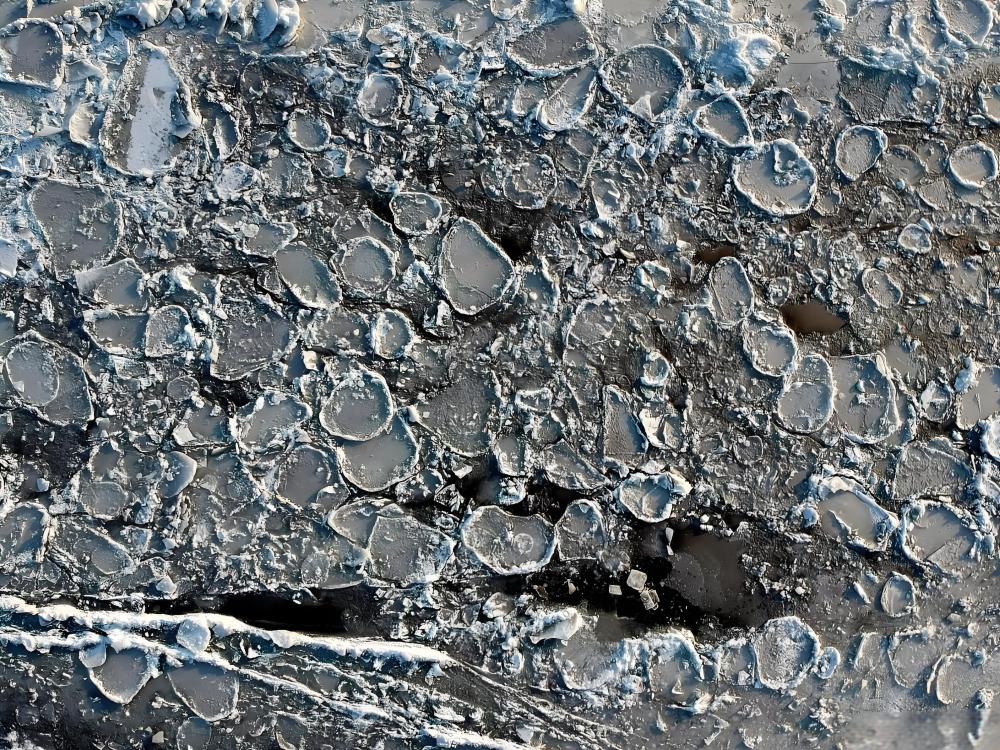

While aluminum doesn’t rust, it can still experience corrosion under certain conditions. Corrosion in aluminum typically manifests as pitting, a localized form of degradation where small pits or holes form on the surface. This occurs when the protective oxide layer is compromised, often due to exposure to aggressive substances like acids, alkalis, or salts.

Pitting corrosion is less widespread than rust but can still affect aluminum’s appearance and, in severe cases, its structural integrity. For instance, in machining applications, where precision is critical, even minor pitting can impact performance. Understanding the conditions that lead to corrosion is crucial for industries relying on aluminum components.

What Causes Corrosion of Aluminum?

Exposure to Harsh Chemicals

Acidic or alkaline substances, such as those found in industrial environments or cleaning agents, can break down the oxide layer, leading to pitting. For example, prolonged exposure to chloride ions, commonly found in saltwater, can accelerate corrosion.

Galvanic Corrosion

When aluminum is in contact with a more noble metal (like copper or steel) in the presence of an electrolyte (like water), galvanic corrosion can occur. This electrochemical reaction causes aluminum to corrode faster as it acts as the anode in the circuit.

Environmental Conditions

High humidity, extreme temperatures, or polluted air can increase the likelihood of corrosion. For instance, aluminum components used outdoors in coastal areas are more susceptible due to salt-laden air.

Mechanical Damage

Scratches or abrasions that disrupt the oxide layer can expose the underlying aluminum, making it vulnerable to corrosion if not repaired naturally by the oxide reformation process.

Understanding these factors is vital for industries like machining, where aluminum components must withstand diverse conditions while maintaining precision and reliability.

How to Prevent Aluminum Corrosion?

Material Selection

Choosing the right aluminum alloy is key. Alloys like 6061 or 5052 are known for their excellent corrosion resistance, making them ideal for machining applications where durability is essential

Anodizing

Anodizing is a process that thickens the natural oxide layer on aluminum, enhancing its resistance to corrosion and wear. This electrochemical treatment is widely used in industries to protect aluminum parts, such as those in aerospace or automotive manufacturing.

Coatings

Applying paints, powder coatings, or sealants can provide an additional barrier against environmental factors. These coatings are particularly useful for aluminum components exposed to harsh conditions, such as marine environments.

Avoiding Galvanic Corrosion

Use insulating materials, such as gaskets or coatings, to separate aluminum from dissimilar metals. This prevents electrochemical reactions that could accelerate corrosion.

Regular Maintenance

Routine inspections and cleaning can help identify and address early signs of corrosion. For machined parts, ensuring proper storage in dry, controlled environments can minimize exposure to corrosive elements.

By implementing these strategies, manufacturers can extend the lifespan of aluminum components, ensuring they perform reliably in demanding applications.

How to Clean Aluminum Corrosion?

- Mild Cleaning Solutions

Use a mixture of water and mild detergent or vinegar to gently clean corroded areas. Avoid harsh chemicals that could further damage the oxide layer. A soft brush or cloth can help remove surface corrosion without scratching the aluminum.

- Abrasive Cleaning

For stubborn corrosion, such as pitting, use fine-grade steel wool or a non-abrasive pad to gently scrub the affected area. Follow up with a thorough rinse and drying to prevent further corrosion.

- Chemical Treatments

Commercial aluminum cleaners or phosphoric acid-based solutions can effectively remove corrosion. Always follow manufacturer guidelines and wear protective gear when using chemical treatments.

- Polishing

After cleaning, polishing the aluminum with a metal polish can restore its shine and help protect the surface. This is particularly useful for aesthetic components in machining projects.

Regular cleaning and maintenance can prevent minor corrosion from escalating, preserving the integrity of aluminum parts in industrial applications.

Application of the Property That Aluminum Doesn’t Rust

Aerospace

Aluminum’s lightweight and rust-resistant nature makes it ideal for aircraft components, such as fuselage panels and structural parts. Its ability to withstand atmospheric conditions ensures longevity and safety.

Marine Industry

In marine environments, where saltwater exposure is a constant challenge, aluminum’s corrosion resistance is invaluable. Boat hulls, fittings, and other components benefit from aluminum’s durability.

Automotive Manufacturing

Aluminum is widely used in car frames, wheels, and engine components due to its strength-to-weight ratio and rust resistance. This ensures vehicles remain reliable even in wet or snowy conditions.

Construction

Aluminum’s resistance to rust makes it a popular choice for window frames, roofing, and cladding in buildings. Its low maintenance requirements reduce long-term costs.

Consumer Goods

Aluminum is found in cookware, smartphones, laptops, and packaging materials due to its durability and aesthetic appeal.

Rust vs. Corrosion

While often used interchangeably, rust and corrosion are not the same.

| Feature | Rust | Corrosion |

| Occurs in | Iron and steel | Most metals |

| Appearance | Reddish-brown flakes | Can be white, gray, black, or green depending on the metal |

| Chemical Process | Iron + Oxygen + Water = Iron Oxide | Varies by metal, e.g., aluminum oxide in aluminum |

| Damage | Progressive and weakening | Can be self-limiting or progressive |

Understanding this distinction is essential, especially in industries like aerospace or marine, where materials selection is critical for safety and durability.

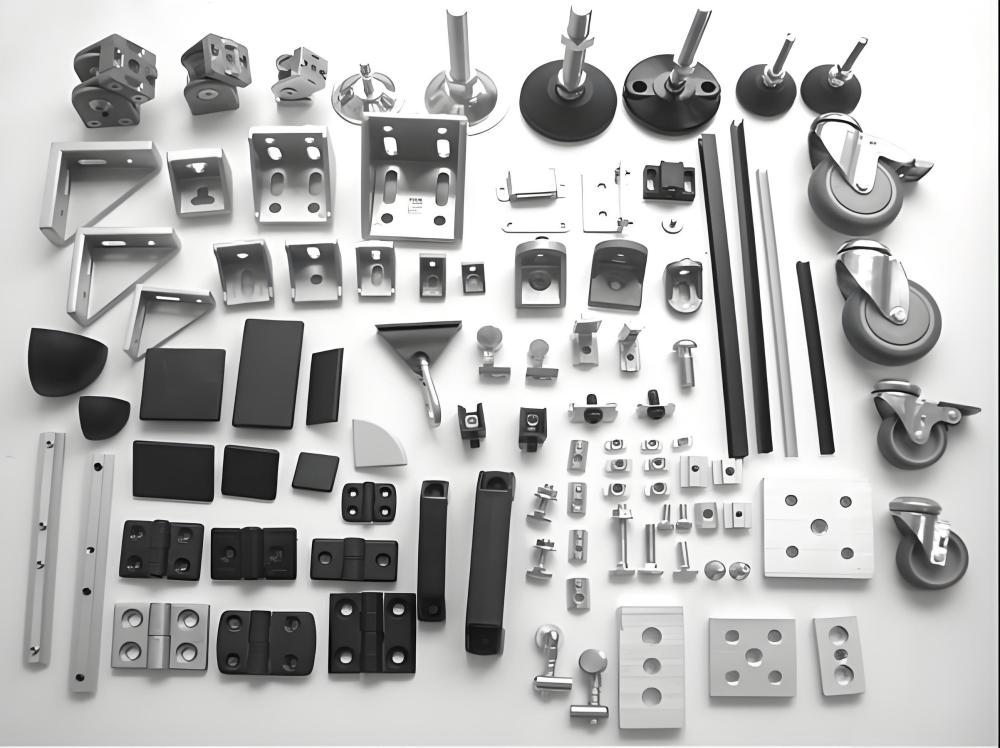

Why Choose Aluminum for Your Machining Needs?

Aluminum’s unique properties make it a standout choice for machining applications. Its resistance to rust, lightweight nature, and versatility allow manufacturers to create high-quality components that meet stringent performance requirements. Whether you’re producing parts for aerospace, automotive, or marine industries, aluminum delivers durability and reliability.

At Precionn, we specialize in precision machining, leveraging aluminum’s exceptional properties to deliver top-tier components for international clients. Our expertise in CNC machining ensures that every part meets the highest standards of quality and performance. Visit our website to learn how Precionn can support your next project with custom aluminum solutions that stand up to the toughest conditions.