Metal CNC Machining

Due to their high strength, high hardness, and high toughness, metal materials are widely used across various industries. The primary manufacturing processes include CNC milling, CNC turning, and grinding. The main metal materials include aluminum alloys, brass, copper, steel, and titanium alloys. Precionn has extensive experience in metal material processing and is well-versed in the machining characteristics of various materials. Regardless of the material you choose, we can deliver efficiently, with high quality, and quickly.

Different Metal Machining Materials

| Material | Introduction | Picture |

|---|---|---|

| Aluminum | Aluminum is lightweight but has high strength, excellent machinability, and corrosion resistance. The processed products have a beautiful appearance and a wide range of post-processing options, including sandblasting, anodizing, baking paint, electroplating, and other treatments. Due to its excellent material properties, it is widely used in aerospace, automotive, consumer products, and automation equipment industries Common alloys: Aluminum 1100; Aluminum 3103; Aluminum 2024; Aluminum 5052; Aluminum 5083; Aluminum 6061, 6061-T6; Aluminum 6063, 6063-T6; Aluminum 6082; Aluminum 7075, 7075-T6; Aluminum ADC12 (A380) |

|

| Brass | Brass material has excellent corrosion resistance, excellent mechanical processing performance, good stability and conductivity, making it widely used in the production of bathroom hardware such as faucets and water pipes; Brass can be used to make musical instruments, precision measuring tools, optical instruments. In addition, brass has a wide range of applications in the fields of construction, mechanical manufacturing, electronics, and automobiles. Common alloys: CuZn5, CuZn10, CuZn20, CuZn35, CuZn35Pb1, CuZn36Pb3, CuZn39Pb1 |

|

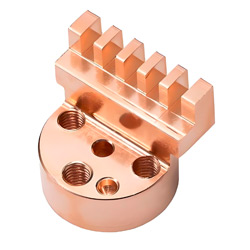

| Copper | Purple copper, also known as red copper, has good electrical and thermal conductivity, excellent plasticity, and is easy to process by hot and cold pressing. Mainly used in the power industry for cables, transformers, switches, plug-in components and connectors, motor manufacturing such as stators, rotors, shaft heads and hollow wires, high-frequency emission tubes in the electronics industry, and integrated circuit industry. Common alloys: Copper C101 (T2), Copper C103 (T1), Copper C103 (TU2), Copper C110 (TU0) |

|

| Steel | The characteristics of steel mainly include high strength, lightweight, good overall rigidity and deformation ability, excellent plasticity and toughness, ability to withstand dynamic loads well, and poor fire resistance and corrosion resistance. Widely used in the construction industry, automotive industry, shipbuilding industry, energy industry, and machinery manufacturing industry. According to the different quality of materials, steel can be divided into: Low carbon steel, medium carbon steel, high carbon steel, low alloy steel, medium alloy steel, high alloy steel |

|

| Stainless steel | Stainless steel material has excellent corrosion resistance, which enables it to work continuously in acidic and alkaline environments. In addition, it has good heat resistance, high strength, and environmentally friendly materials. Therefore, it has been widely used in fields such as construction, automotive, medical equipment, and food processing. Stainless Steel SUS201, Stainless Steel SUS303, Stainless Steel SUS 304, Stainless Steel SUS316, Stainless Steel SUS316L, Stainless Steel SUS420, Stainless Steel SUS430, Stainless Steel SUS431, Stainless Steel SUS440C, Stainless Steel SUS630/17-4PH, Stainless Steel AISI 304 |

|

| Titanium | Titanium alloy has high strength, good corrosion resistance, and high thermal strength, and is widely used in various fields such as aerospace, chemical industry, marine engineering, shipbuilding, medical field, energy industry, sports and leisure, automotive industry, drilling industry, and other industries. Alloy grade TA1, TA2, TA3, TA4, TC1, TC2, TC3, TC4 |

|

Get In Touch

- 510, Building M, Flying Pigeon Industrial Park, No. 1223 Guanguang Road, Guanlan Street, Longhua District, Shenzhen, Guangdong, China

- +8618688772802

- info@precionn.com

Find Us

Follow Us