Plastic Precision Machining

Due to their low density, light weight, good corrosion resistance, strong stability, ease of processing and molding, and low manufacturing cost, plastics are used in various industries and are increasingly replacing metals. Common processing methods for plastics include injection molding and CNC machining. The main plastic materials include ABS, PE, PMMA, PP, PC, PTFE, PA, PEEK, and POM. Precionn understands the thermoplastic properties, shrinkage rates, and processing deformation characteristics of various plastic materials, enabling us to reasonably formulate manufacturing processes for plastic products.

Different Plastic Machining Materials

| Material | Introduction | Picture |

|---|---|---|

| ABS | ABS resin is currently the largest and most widely used polymer in production, with an opaque ivory colored granular appearance and high glossiness. Easy to process, surface smoothness, thermal stability, geometric stability, good impact resistance, good insulation, acid and alkali resistance, low creep resistance, high hardness, good rigidity, low price, poor weather resistance, poor thermal performance, average fluidity, small shrinkage rate, The biggest application areas of ABS resin are automobiles, electronic appliances, and building materials. The use in the automotive field includes many components such as car dashboard, exterior panel, interior decorative panel, steering wheel, sound insulation panel, door lock, bumper, ventilation duct, etc. In terms of electrical appliances, it is widely used in electronic appliances such as refrigerators, televisions, washing machines, air conditioners, computers, copiers, etc. In terms of building materials, ABS pipes, ABS sanitary ware, and ABS decorative panels are widely used in the building materials industry. In addition, ABS is widely used in the packaging, furniture, sports and entertainment products, machinery, and instrumentation industries. |

|

| PE | Polyethylene (PE) is the most widely produced variety of synthetic resins, mainly including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and some products with special properties. Good acid and alkali resistance and chemical solvent properties, good fluidity, good insulation, easy to absorb dust on the surface, low brittleness temperature (-75 °C), white semi transparent, prone to environmental stress cracking, good flexibility. Widely used, mainly for manufacturing films, packaging materials, containers, pipelines, monofilaments, wires and cables, daily necessities, etc. |

|

| PMMA | High transparency, good impact resistance, non fragile, anti-aging, good weather resistance, low hardness, poor wear resistance, relatively brittle. PMMA products have very low birefringence, making them particularly suitable for making DVDs, etc PMMA has the advantages of light weight, low cost, and easy molding. Its molding methods include casting, injection molding, mechanical processing, thermoforming, etc. Especially injection molding, it can be produced in large quantities, with a simple process and low cost. Therefore, its application is becoming increasingly widespread. Currently, it is widely used in instrument parts, automotive headlight acrylic rods, optical lenses, transparent pipes, etc. |

|

| PP | Rigid, resistant to bending, good toughness, fatigue resistance, lightweight, still has good mechanical properties at high temperatures, good acid, alkali, and chemical solvent resistance, good fluidity, good insulation, poor weather resistance, easily brittle at 0 °C, and resistant to stress cracking. Automotive industry (mainly using PP containing metal additives such as mudguards, ventilation ducts, fans, etc.), machinery (dishwasher door liners, dryer ventilation ducts, washing machine frames and covers, refrigerator door liners, etc.), daily consumer goods (lawn and gardening equipment such as lawn mowers and sprayers, etc.) |

|

| PC | Good impact resistance, good insulation, geometric stability, good heat resistance, low brittleness temperature (-130 °C), good weather resistance, low creep resistance, high transparency, good mechanical properties, poor solvent resistance, stress cracking, poor fatigue resistance, poor fluidity, low shrinkage rate, easy hydrolysis in boiling water, good glossiness, and high friction coefficient. The application development of polycarbonate is moving towards high composite, high functionality, specialization, and serialization. Currently, various products have been launched, including optical discs, automobiles, office equipment, enclosures, packaging, pharmaceuticals, lighting, films, and more. |

|

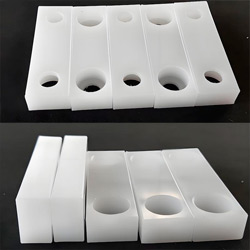

| PTFE | Polytetrafluoroethylene (PTFE) is one of the most corrosion-resistant materials in the world today, earning it the nickname of "Plastic King". It can be used for a long time in any type of chemical medium, such as PTFE seals, gaskets, and washers PTFE seals, gaskets, and sealing washers are made by molding suspended polymer PTFE resin. Compared with other plastics, polytetrafluoroethylene has excellent chemical corrosion resistance and temperature resistance, and it has been widely used as a sealing material and filling material. |

|

| PA (Nylon) | PA has good comprehensive performance, including mechanical properties, heat resistance, wear resistance, chemical resistance, and self-lubricating properties. It has a low coefficient of friction, a certain degree of flame retardancy, and is easy to process. It is suitable for filling and reinforcing glass fibers and other fillers to improve performance and expand application scope. This type of product has a wide range of applications and is a good material for replacing metals such as steel, iron, and copper with plastic. It is an important engineering plastic. |

|

| PEEK | Peek material is a high-performance engineering plastic with characteristics such as high temperature resistance, chemical stability, good mechanical properties, and biocompatibility. It can manufacture and process various mechanical components, such as automotive gears, oil screens, shift starting discs, aircraft engine components, automatic washing machine wheels, medical equipment components, etc. It has been applied in aerospace, automotive manufacturing, electronics and electrical, medical and food processing fields. |

|

| POM | POM material has low strength, but good thermal stability, is not easily decomposed, has a wide processing temperature range (about 50 ℃), and has good acid-base stability. It is an engineering plastic with excellent comprehensive performance. Has good physical, mechanical, and chemical properties, especially excellent friction resistance. Commonly known as Saigang or Duogang, it is the third largest general-purpose engineering plastic. Suitable for producing wear-resistant parts, transmission parts, as well as chemical and instrumentation components. |

|

Get In Touch

- 510, Building M, Flying Pigeon Industrial Park, No. 1223 Guanguang Road, Guanlan Street, Longhua District, Shenzhen, Guangdong, China

- +8618688772802

- info@precionn.com

Find Us

Follow Us